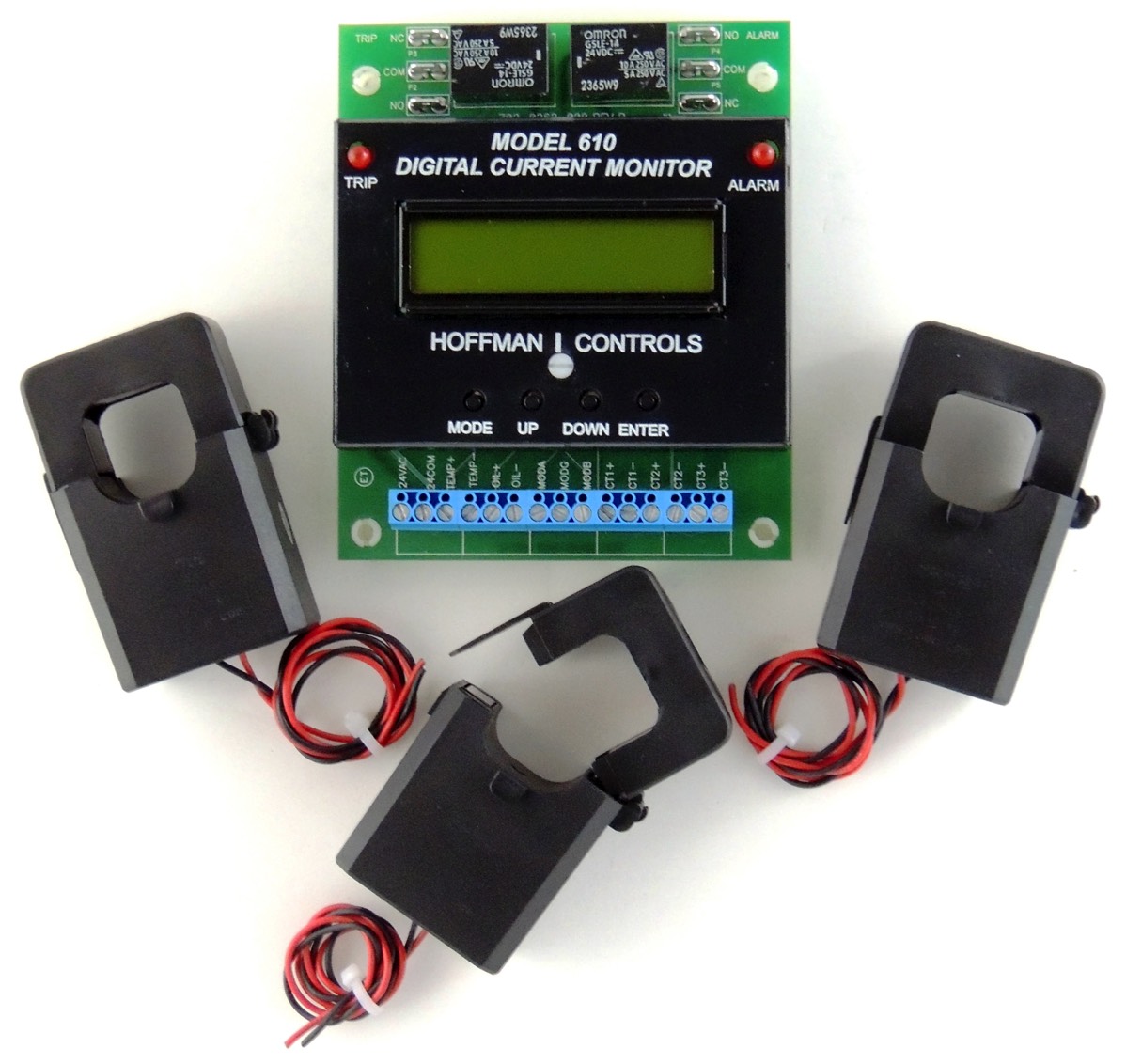

610

Digital Overcurrent & Temperature Motor Protector

The Digital 610 Motor Protector is a micro controller based motor and compressor protector that provides over-current and temperature protection for across-the-line or part winding motors and their A/C compressors. The control has a current sensing circuit module that derives information from up to three C.T.s (current transformers). When a current in any phase exceeds the pre-determined adjustable “trip level”, the control de-energizes the across-the-line motor starter, contactor or control circuit. When currents exceed the trip point, the control calculates the energy dissipated in the motor due to the over current and trips before damage can occur. The greater the current above “trip level”, the shorter the time to trip. The lesser the current above “trip level”, the longer the time to trip. The time to trip is two seconds for locked rotor and can be over 20 minutes for marginal overloads.

The Digital 610 also verifies correct motor phase rotation upon power up. If the rotation is out of sequence, the controller will shut the motor off within 2 seconds after power up. The controller can also be set to trip on an adjustable phase imbalance.

The Digital 610 has a temperature sensing circuit that uses up to two temperature sensors that are typically attached to an A/C compressor's exhaust (discharge) line and and/or oil crankcase. The controller will trip the compressor's motor off when the exhaust temperature exceeds an adjustable trip point or when the crankcase oil temperature is too low or high.

Input power is provided by 24 VAC. Two sets of isolated Form C relay contacts are provided. The TRIP relay is normally closed and will open during a trip condition. The ALARM relay can be programmed to close on particular conditions and is used for alerting at a remote site.

A optional Modbus RTU interface is available in the controller which allows all parameters to be set over Modbus and all present settings and current input and output values to be read over Modbus.

The Digital 610 also verifies correct motor phase rotation upon power up. If the rotation is out of sequence, the controller will shut the motor off within 2 seconds after power up. The controller can also be set to trip on an adjustable phase imbalance.

The Digital 610 has a temperature sensing circuit that uses up to two temperature sensors that are typically attached to an A/C compressor's exhaust (discharge) line and and/or oil crankcase. The controller will trip the compressor's motor off when the exhaust temperature exceeds an adjustable trip point or when the crankcase oil temperature is too low or high.

Input power is provided by 24 VAC. Two sets of isolated Form C relay contacts are provided. The TRIP relay is normally closed and will open during a trip condition. The ALARM relay can be programmed to close on particular conditions and is used for alerting at a remote site.

A optional Modbus RTU interface is available in the controller which allows all parameters to be set over Modbus and all present settings and current input and output values to be read over Modbus.

Applications

See a YouTube video demonstration of the Model 610.

- A/C compressor motor protection from overcurrent, current imbalance, or temperature problems.

- Part winding motor starters

- Protection of any electrical load such as fans, pumps, blowers, conveyors, machine tools, and elevators.

Features

- Field selectable current trip level adjustment from 5 to 250 amps for three-phase or single phase circuits

- A settable number of automatic trip resets with adjustable time delay between trip and reset

- Manual push button reset or reset over Modbus remotely

- Current transformers are located remotely from the circuit board

- Two isolated output Form C (N.O./N.C.) relays for trip and alarm

- Over current protection timing depends on excess energy dissipated thereby eliminating nuisance trips

- Up to two temperature sensors can be used to trip on high or low temperature values (such as discharge line and crankcase oil)

- Trips on adjustable phase imbalance for three-phase systems

- Detects improper phase rotation

- Loss of power auto recovery

- Relay stage LED indicators

- Alarm relay can be set to alarm on each trip, after any resettable trip, or only when manual reset is required

- Large 32 character LCD screen for readout of values and setting parameters using a menu system

- Modbus RTU available so that all parameters can be set or read remotely and all input and output values can be read remotely

- Modbus baud rate, slave ID, and parity can be set using the menu system

Data Sheets

The following two models are earlier versions of the 610