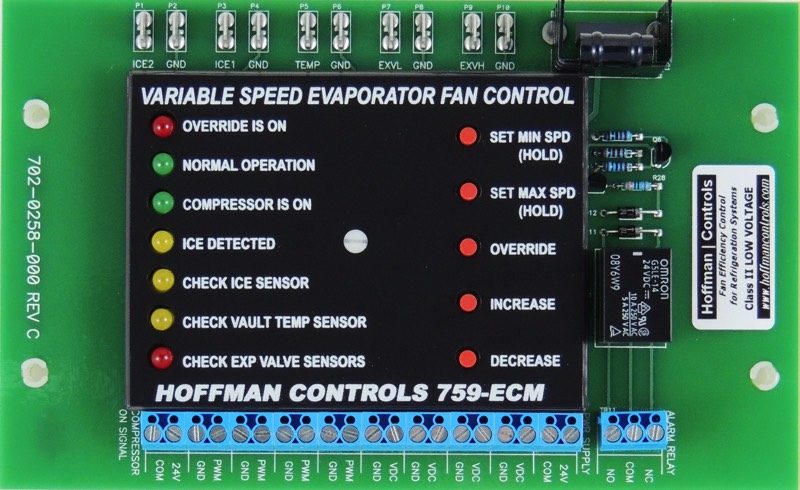

759-ECM

Refrigeration Evaporator Fan Controller

The 759-ECM controller is designed for walk-in and reach-in coolers and freezers that have continuously variable speed ECM evaporator fan motors, such as the ICE-59, the ICE-142, and the Hoffman variable speed EC motor. This controller provides maximum efficiency, reduced compressor run time, reduced product shrinkage, and increased product shelf life by continuously varying the evaporator fan speed depending on the vault temperature.

It is well-known that a two speed evaporator fan and control can provide energy savings by reducing the air flow during the compressor-off part of the cycle. This controller takes the technology to a new level by continuously varying the fan speed as the vault temperature rises during the compressor-off period using an adaptive algorithm to set the exact speeds.

The only sensors used by this control are temperature sensors, used to detect when the expansion valve is operating, the vault temperature, and the coil temperature.

It is well-known that a two speed evaporator fan and control can provide energy savings by reducing the air flow during the compressor-off part of the cycle. This controller takes the technology to a new level by continuously varying the fan speed as the vault temperature rises during the compressor-off period using an adaptive algorithm to set the exact speeds.

The only sensors used by this control are temperature sensors, used to detect when the expansion valve is operating, the vault temperature, and the coil temperature.

Applications

- Continuously variable speed ECM motors

- Walk-in and reach-in coolers and freezers

Features

- Optimally varies the speed of the evaporator fan motor

- Automatically adjusts to thermostat settings and the refrigeration cycle

- Simple installation does not require changes to thermostat or compressor wiring

- No programming or set-up necessary for basic operation

- Adjustable maximum and minimum fan speeds

- LED indicators for error conditions and normal operation indication

- PWM and 0-10V outputs for control of ECM Motors

- Up to 12 motors may be controlled simultaneously

- Override button allows bypass of control to keep fans at maximum speed

- Frost detection for medium temperature applications sets fan to maximum speed

- External alarm dry contract relay for error conditions

Data Sheets and Instructions

Videos

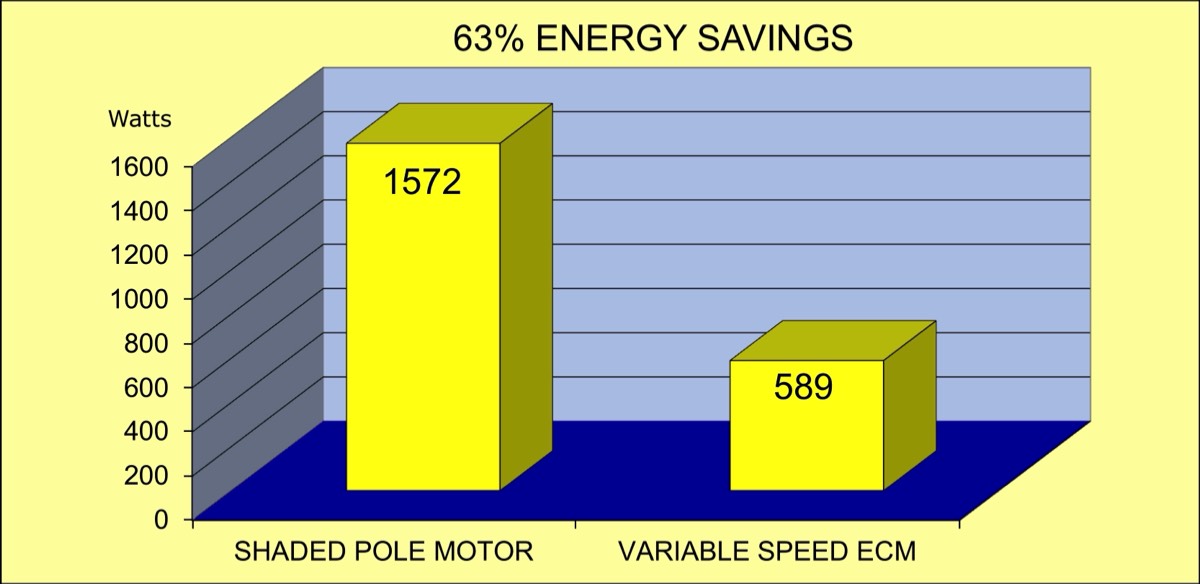

The chart above shows the average power consumption in Watts for a mid-temperature walk-in cooler as tested in our laboratory. This represents a 63% reduction in energy. Switching from a shaded pole motor to an EC motor reduces the energy required. However the variable speed fan control introduces an additional 544 Watts of power reduction due to reduced number of compressor cycles required. In all our tests, the variable speed fan control is the most efficient compared to two-speed and single-speed systems.

EC Motors are now available from Hoffman Controls

1/15 hp Commercial Evaporator Fan Motors

– IMESA Variable Speed for use with this 759-ECM controller

Contact us for details

1/15 hp Commercial Evaporator Fan Motors

– IMESA Variable Speed for use with this 759-ECM controller

Contact us for details